Safety improvements and early return-to-work have carried many school districts insured by SFM to the head of the class.

Through years of consistent effort and working in partnership with SFM, school districts have seen their experience modification factors drop as much as 50 points over time.

In a big organization like a school district, getting everyone to support and cooperate with safety efforts is essential.

Turning around a trend of high losses can be challenging in school districts. But those who’ve done it have seen their efforts pay off in the form of lower workers’ compensation premiums, reduced need to hire substitutes and improved employee morale.

Return-to-work programs key to controlling costs

Implementing strong return-to-work programs has been a key factor in reducing losses for many school districts insured by SFM.

Having light-duty, transitional jobs identified in advance helped the South Washington County Schools get injured workers with medical restrictions back to work sooner, said Assistant Director of Human Resources Theresa Lenarz. The Cottage Grove, Minnesota-based district saw a 73-point e-mod drop over six years, reducing its workers’ compensation costs by tens of thousands of dollars.

Their go-to light-duty assignments include shredding paper, alphabetizing items in their student information center and helping out with special projects like laminating or cutting out paper items.

Injured workers tend to appreciate being able to return to work even when medical restrictions prevent them from doing their regular jobs, Lenarz said.

“By and large, they’re really excited because they want to transition back into work,” she said. “It gives them the opportunity to try something new while they’re recovering.”

Implementing strong return-to-work programs has been a key factor in reducing losses for many school districts insured by SFM.

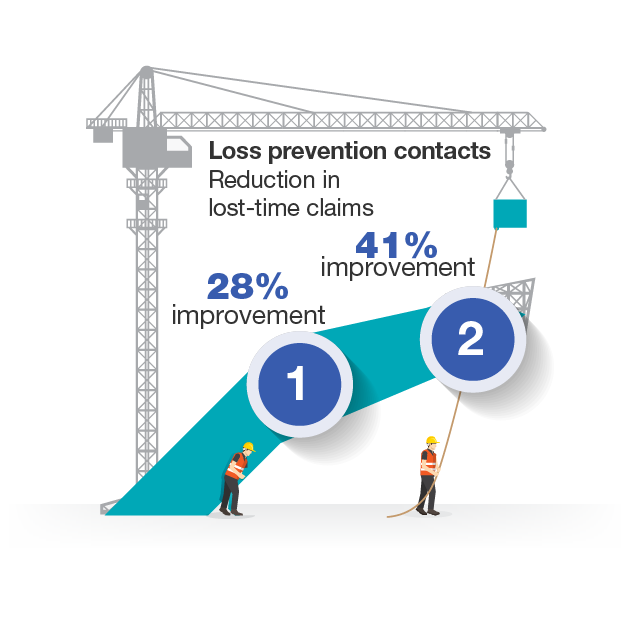

Early return-to-work can have a significant impact on any organization’s e-mod. When injured employees return to work before the state’s waiting period ends, the claim is considered medical-only, and loss costs are discounted by 70 percent when calculating the e-mod.

Focus on major loss sources for safety improvements

School districts have also made great strides in safety by focusing on preventing the most common injuries.

In schools, which have big parking lots with multiple entrances, snow- and ice-related slips and falls are often a major risk.

The St. Louis County (Minnesota) Schools district, which saw a 45-point e-mod drop over six years, has worked to prevent winter slips and falls in many ways, said SFM Loss Prevention Specialist Joe Morin.

Examples of the district’s tactics include:

- Using proactive and responsive snow- and ice-control measures

- Educating staff on slip-and-fall prevention tactics during classroom safety education courses

- Posting SFM’s winter slip-and-fall prevention posters and other penguin campaign materials

- Providing custodians with traction footwear to prevent falls in slippery conditions

- Experimenting with liquid brine pretreatment

To help identify and address additional risk factors, SFM assists the district by conducting comprehensive site safety audits, workstation ergonomic evaluations and safety training. The district is very good about correcting any safety issues discovered, Morin said.

“They place a high value on safety and work together to make meaningful improvements,” Morin said. “Clearly, they’ve been very effective.”

Getting buy-in from employees helps make safety programs successful

In a big organization like a school district, getting everyone to support and cooperate with safety efforts is essential.

The Chisago Lakes School District, based in Lindstrom, Minnesota, would not have seen its e-mod drop 41 points over seven years if not for the support of the district’s superintendent, building principals, buildings and grounds directors and many more, said Director of Business Services Heide Miller.

“You’ve got to have support from the top down, and get everyone involved that you can,” Miller said. “It’s a district-wide effort. Everyone has a little part to play, and that really helps out.”

Roles might include giving safety talks in staff meetings, reporting or correcting unsafe conditions or simply wearing required personal protective equipment.

While e-mods don’t change overnight, they certainly can improve over time.

“The fact that organizations as complex as school districts can see reductions in their losses should be encouraging to all employers,” Morin said. “It shows that with persistent effort over time, it really is possible to see substantial and sustainable improvement.”