With the shift to remote and hybrid work in recent years, many employers are quickly learning how to support employees in their new work environments. As with in-office workers, remote and hybrid employees are subject to cumulative injuries, which are typically a result of poor ergonomics at their workspace.

Common slips, trips and falls are also frequent claims we see from remote and hybrid workers. These types of injuries can be avoided with proper training and preventive measures.

Injury prevention

As an employer, you have the ability to help prevent injuries among your employees, regardless of where they’re working.

“Preventing an injury before it happens really starts with the employer,” said Mike Fetting, SFM Loss Prevention Specialist. “Educating employees on ergonomic best practices, and home office maintenance and safety when they’re working remotely can help reduce the likelihood of injury.”

He recommends encouraging employees to set up their home or remote office spaces with these tips in mind:

Keep your office tidy and free of hazards

- Organize cords so they’re tied up and tucked away

- Eliminate clutter, especially in walking paths

- Clean up spills immediately to avoid slips and falls

Optimize your desk setup for proper ergonomics

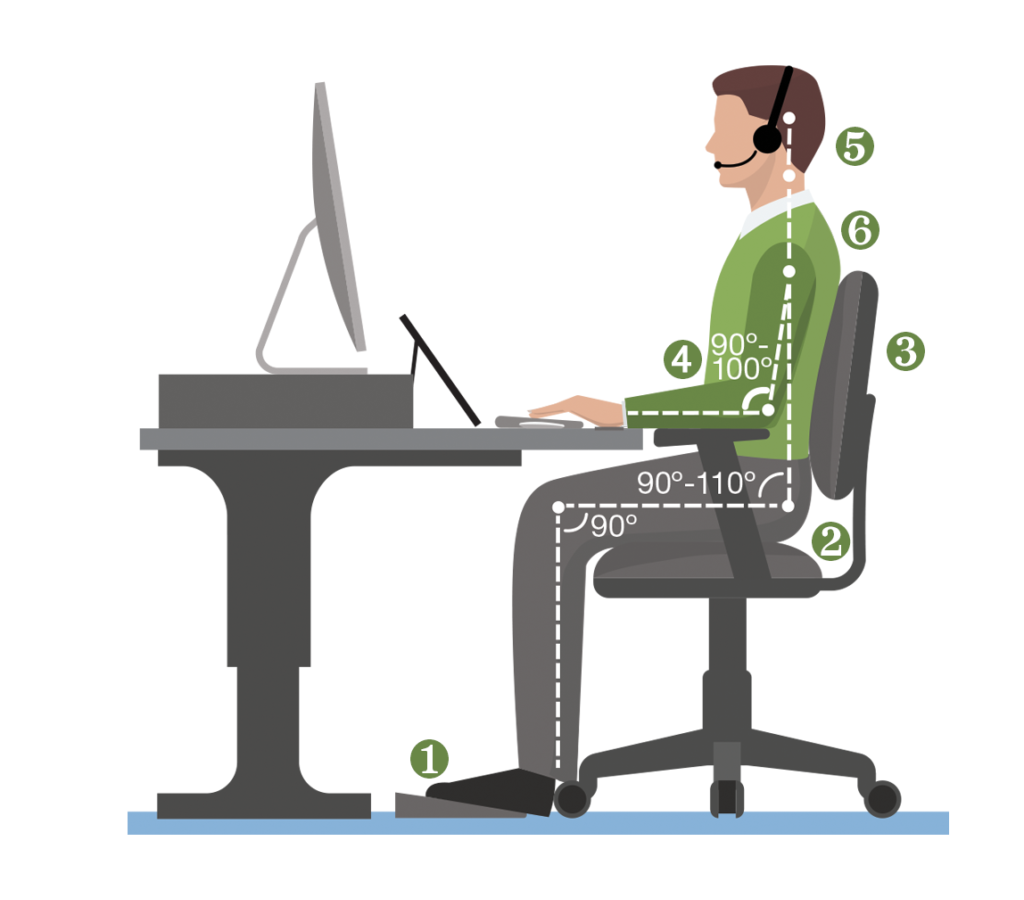

- Sitting desks. Maintain neutral posture at the desk by adjusting your seat so you can keep your feet resting comfortably on the floor or on a footrest. Hips should sit at a 90-to-110-degree angle and your upper arms should rest comfortably at your side, with elbows at a 90-to-100-degree angle. The backrest of your chair should meet your back as you sit up straight and should support the natural curve of your back.

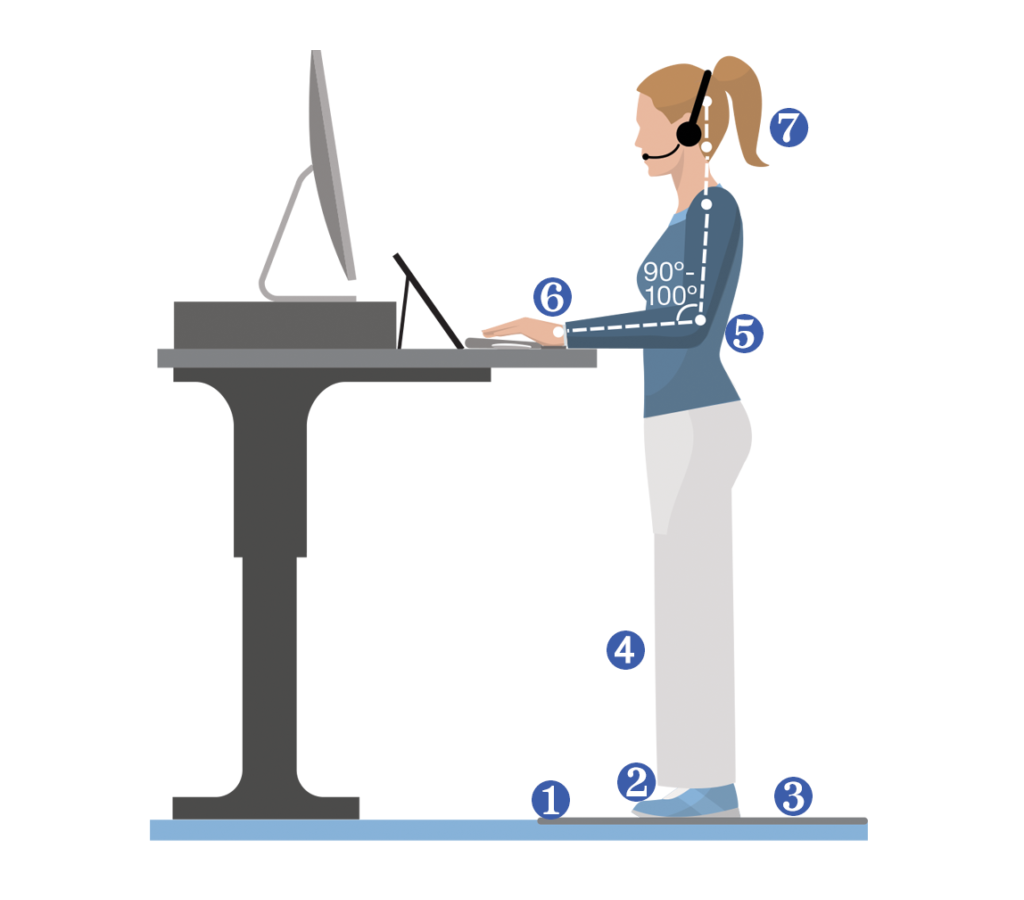

- Standing desks. Situate the desk height and your body so your upper arms can rest comfortably at your side, with elbows at a 90-to-100-degree angle, and your feet align below your head and hips. Wrists should be held straight, not pressed into the edge of the desk. Wear shoes with insoles or stand on an anti-fatigue mat with beveled edges that sits flat on the floor.

Utilize ergonomic tools and proper placement of office technology

- Adjustable monitor stands. Center the monitor in front of your keyboard and keep the top of the screen at eye level, or slightly below eye level for those who use bifocals. Use adjustable monitor stands to achieve the correct height for your body. Your monitor should be about an arm’s length away, but move it closer or increase the font if you find yourself leaning forward.

- Headsets. Go handsfree and eliminate neck issues from cradling a traditional office phone by using an over-the-ear or in-ear headset. Corded or cordless headsets are both better options than a traditional office phone when taking phone calls throughout the day.

- Adjustable chairs. Make sure the height, seat, arms and back are adjustable so you can set your chair to maintain a neutral position, as described above.

- Mouse and keyboard cushions. Your wrists should be raised and level when using your mouse and keyboard, and your keyboard should be set flat. Do not rest your wrists on anything while keying. Your hands should project straight out from your forearms, and not bend back at the wrists.

- Footrests. You may need a footrest to help achieve neutral posture when working at a higher desk. Once you set your chair to the correct height to allow for neutral arm placement, set the footrest below your desk to keep your legs from dangling and take the weight off your thighs.

Individual needs vary

“This guide includes standard practices that most people will find appropriate, but you should find what works for you using these tips as a starting point,” said Fetting. “If you find you prefer to have your knees slightly above your hips, that’s OK. Everyone is different.”

He also suggests that employees change positions at their desks occasionally to reduce the chance of a cumulative injury, which can happen because of repetitive movement or positioning.

“There’s no perfect position that you should remain in 100% of the time,” said Fetting. “Occasionally adjust things, such as raising or lowering your chair or monitors by an inch, to find alternatives that work for you.”

We have more resources to help you educate employees on their role in safety and injury prevention in office settings on our website.

Keep your feet resting comfortably on the floor or on a footrest.

Keep your feet resting comfortably on the floor or on a footrest. Feet should be resting comfortably on an even surface.

Feet should be resting comfortably on an even surface.